Our solid commitment to this extent is

the very reason our product is outstanding.

Customer Delight

We do not only provide products, but also tackle each and every concern our customers may face

with PRECILENCE as the solution.

Want to assemble right away but must adjust shaft

diameter onsite to suit the bearing I.D.

Adjustment takes several days.

After assembly, must take time to adjust rotational

runout accuracy.

Isn’t there a way to cut out runout adjustment?

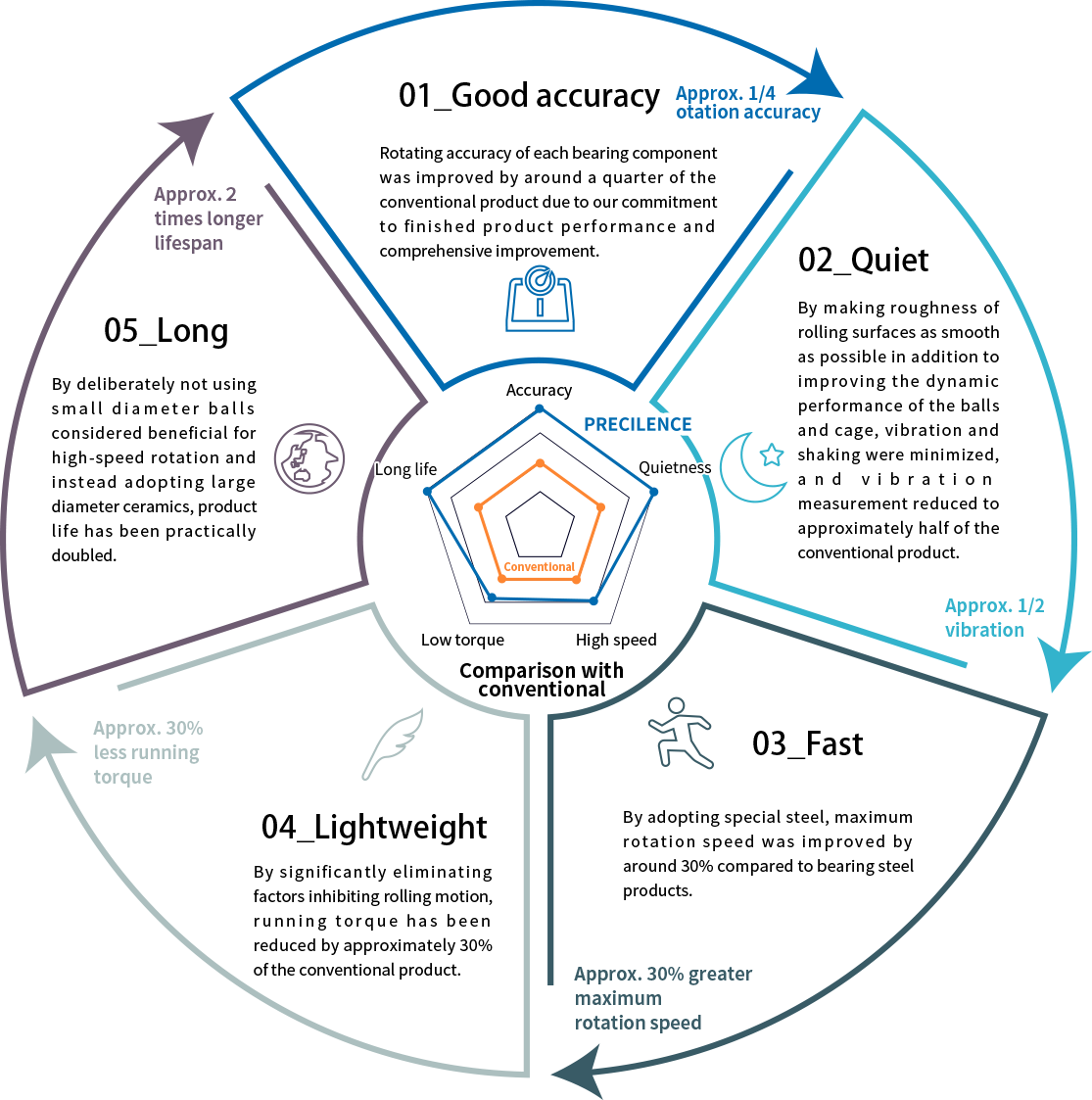

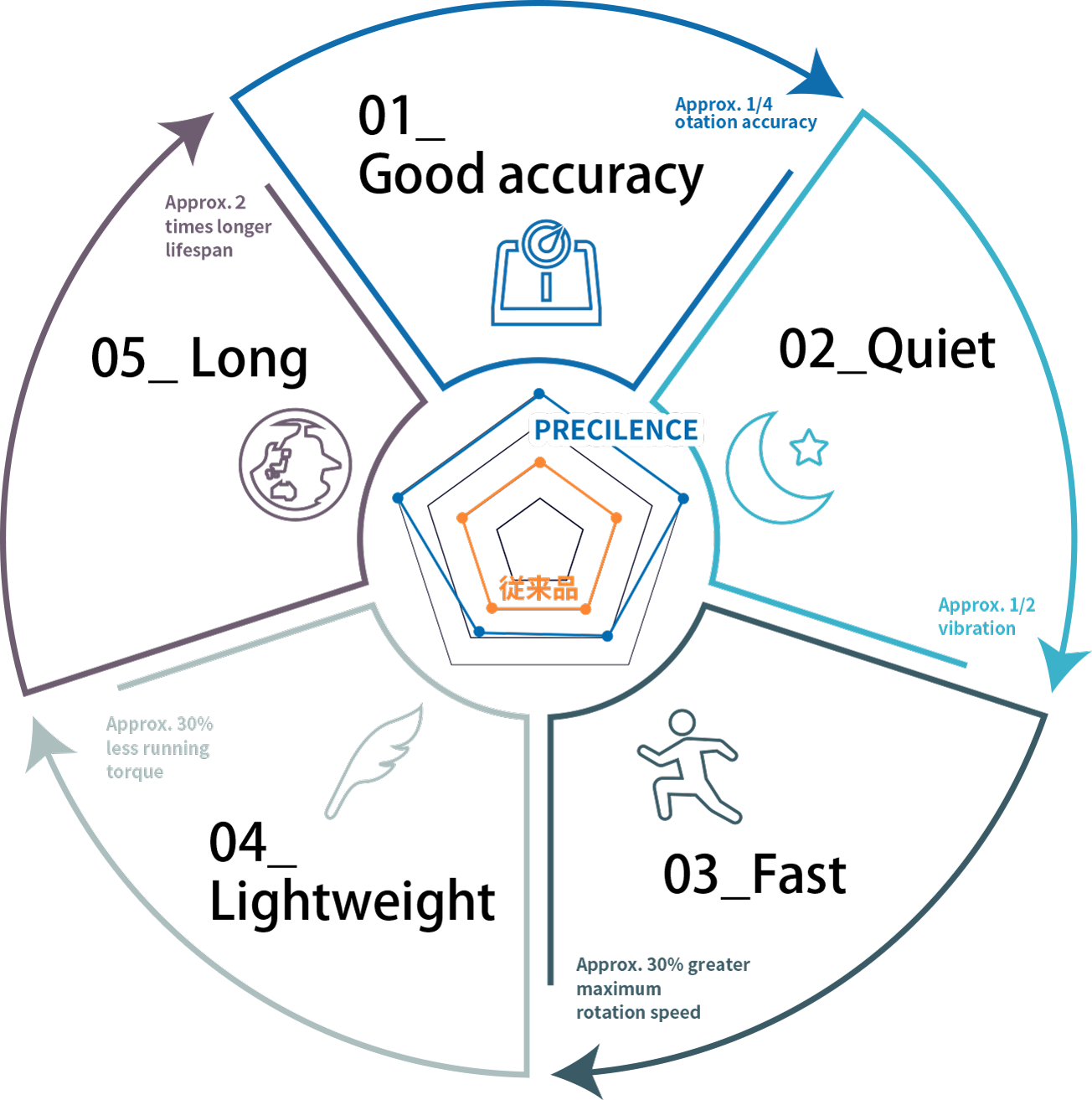

Product Performance

World-class ultra-high accuracy bringing customers delight

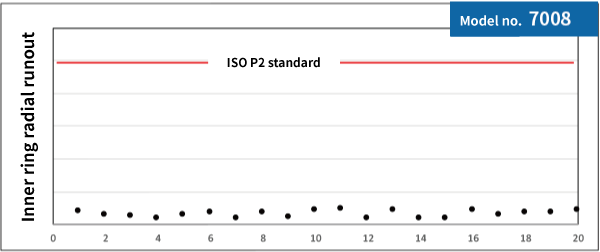

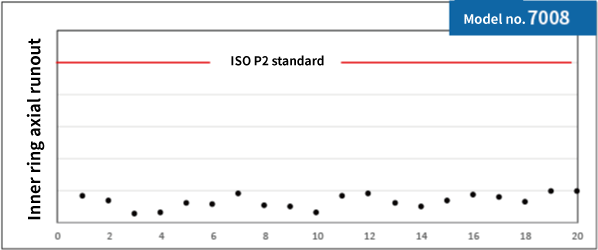

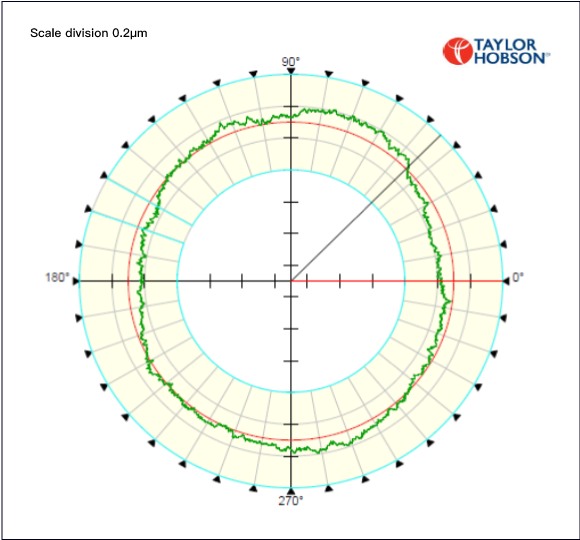

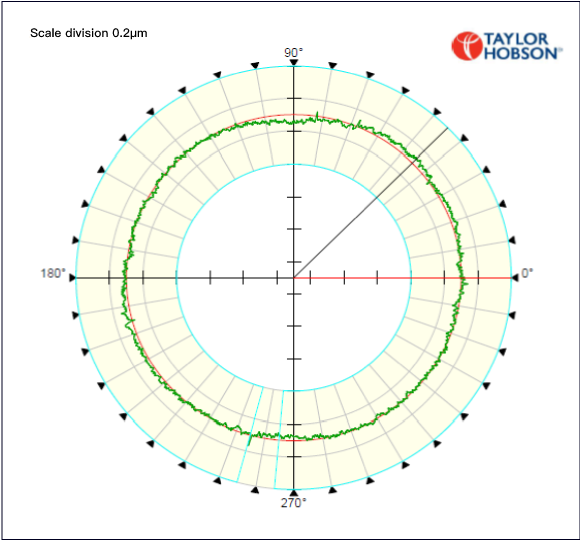

Adopting PRECILENCE realizes high-level runout performance

High accuracy apparent through verification

※Finishing of continuously-machined products

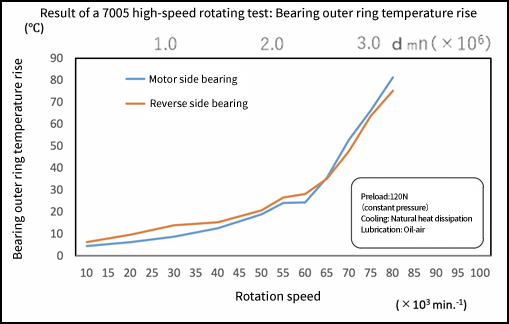

Also supports high-speed rotation

Quality Assurance

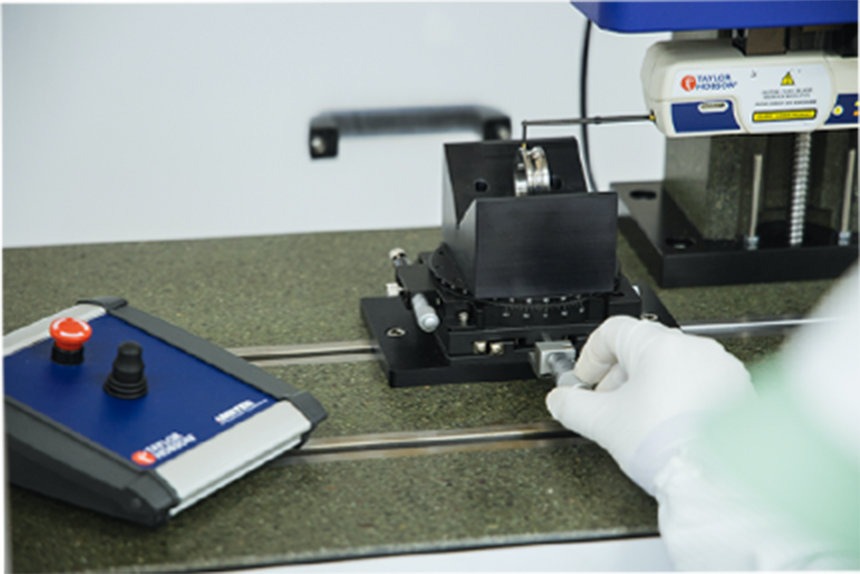

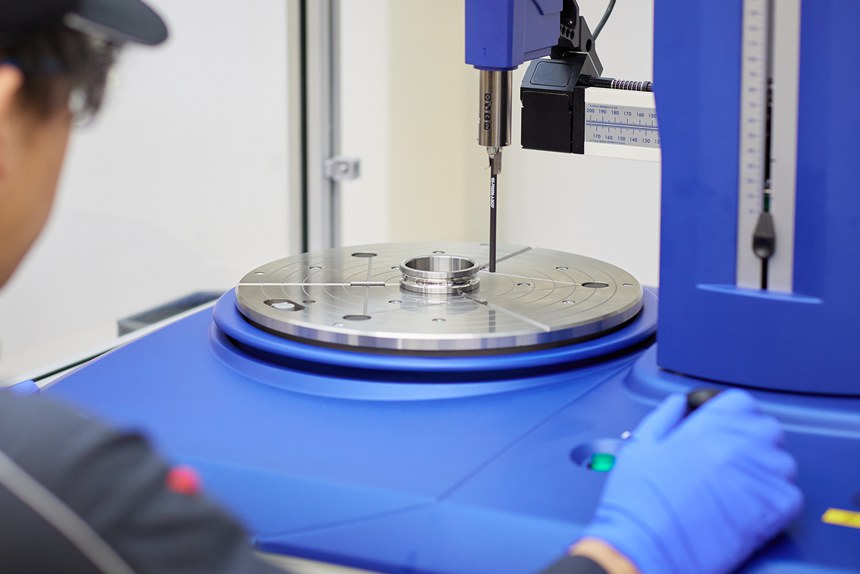

In order to guarantee product quality at a high level, we have carefully selected and maintained our measuring instrumentation also. Returning to measurement principles, we establish various measurement and quality assurance technologies.

Through designs using independently-developed equipment, we have made it possible to measure items not previously measurable, and acquire data previously unobtainable.

Measuring unit

In-process inspection

100% measurement in the grinding process. Only delivering reliable products.

Measurement example

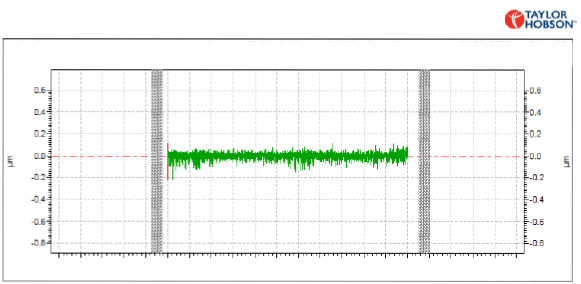

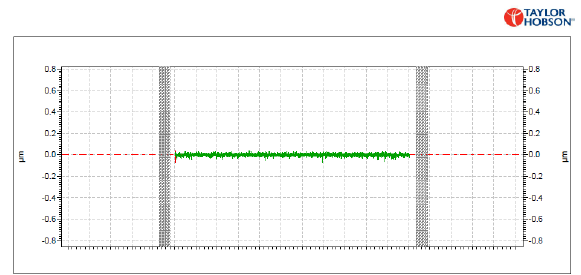

Race roughness measurement

Inner race

roundness

Industrial Science

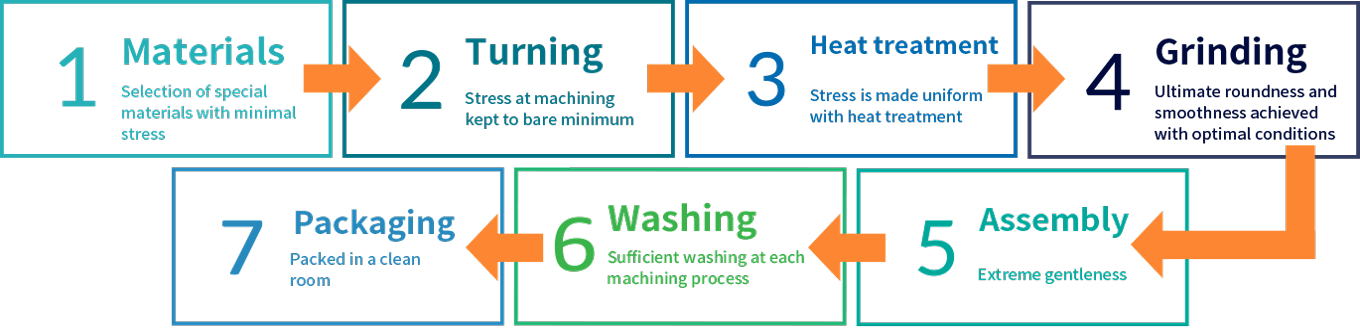

A dedicated PRECILENCE line breathing new life into the conventional bearing machining process

Human Resources

A dedicated PRECILENCE team establishes conditions to produce quality parts in each process, and works with a strong sense of responsibility and pride until the product warranty stage.

Production Environment

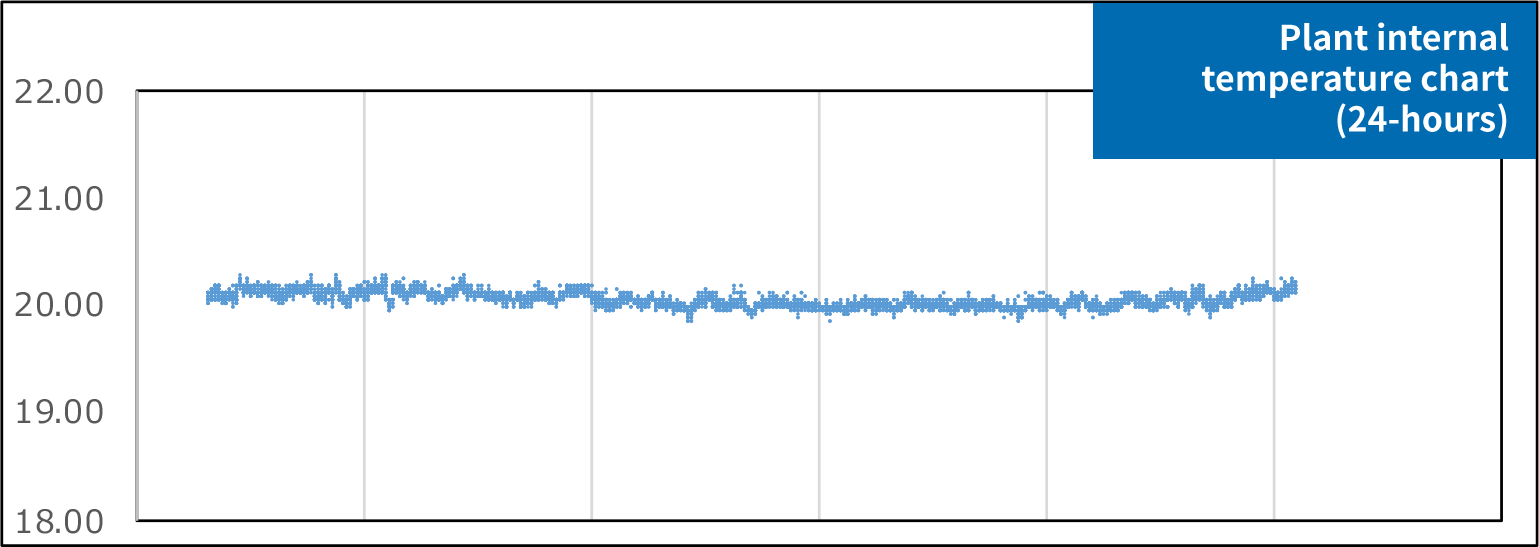

One major factor behind maintaining product accuracy is preparation of the right environment.

By adopting a constant-temperature/constant-humidity structure separated into zones by individual process, measurement error due to temperature change has been eliminated to the maximum extent.

We boast first-class cleanliness as a bearing plant and maintain an environment in which high-quality products can be produced with stability.

■ Thorough contamination control

■ Stringently controlling production plant temperature without impacting finished product accuracy (20℃±0.5℃)

Delivery Date

JTEKT Precision Bearing Corporation has a quick delivery system satisfying our customers’ requirements.

Many bearing manufacturers adopt a made-to-order method, therefore it takes several months from receipt of order to delivery.

JTEKT Precision Bearing Corporation, however, adopts a production system responding to our customers’ needs.